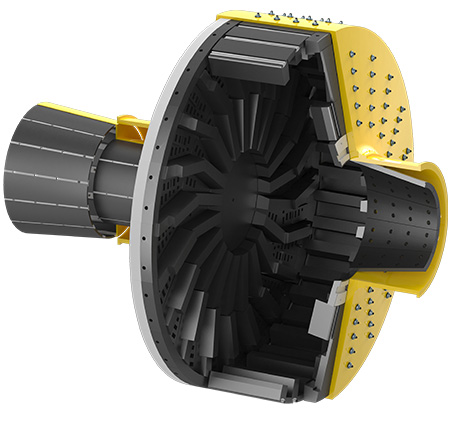

Genel olarak yaş öğütme yapılan değirmenler kauçuk astar için elverişlidir. Uygulamanın alanı iri malzeme beslemesi yapılan Otojen değirmenlerinden çok ince öğütme yapılan bilyalı değirmenlere kadar değişmektedir.

Kuru öğütmelerde de kauçuk astarlama başarılı olarak kullanılabilir fakat bu durumda değirmenin öğütme şartlan ve sıcaklığı iyi etüd edilerek uygun formülasyon seçilmelidir.

Aşağıdaki değirmenlerde kauçuk astarlama başarılı olarak kullanılmıştır.

FKK Güney Oto Lastik Takoz Sanayi ve Ticaret A.Ş. Ülkemizde ilk defa yerli olarak üretimi yapılan kauçuk astar ve lifterbarların öncülüğünü yapmıştır.

1989 yılından bu yana değişik ebatlardaki otojen, çakıl ve bilyalı değirmenlerde kauçuk astar ve liftebarlan başarıyla çalışan firmamız, daha önceleri yurt dışından ithali yapılan malzemelerin ulaştığı ömür ve kalite seviyesine aradan geçen kısa süreye rağmen ulaşmış bulunmaktadır. Karadeniz Bakır işletmeleri A.Ş.'nin Murgul, Samsun ve Sürmene'deki işletmelerinin Otojen, Çakıl ve Bilyalı değirmenlerinde FKK imali kauçuk astar ve lifterbarlar halen başarı ile çalışmaktadır.

Değirmen astarlarımız aşınmaya dayanıklı özel kauçuktan imal edilmektedir. Güvenilir ve montajı kolaydır. Bütün bunlar, yüksek seviyede ekonomik verimliliği garanti etmektedir.

Kauçuk astarın çelik astara göre çok sayıda üstünlükleri vardır. Bunlardan en önemlileri aşağıda çıkarılmıştır.

ÖMÜR

Lastik astar ve lifterbarların ömrü çeliğe nazaran 1-5 misli daha fazla olmaktadır. Öğütme rejiminde hiç bir değişiklik olmazken lastik astarın aşınması daha yavaş olduğu için değirmenin birim zamandaki öğütme kapasitesi daha fazla olmaktadır. Yapılan denemelerde otojen değirmenin en çok aşınan bölgesindeki çelik lifterbar 600 saat çalışarak 75.000 ton cevher işledikten sonra devre dışı kalırken aynı bölgedeki lastik lifterbar minimum 2700 saat çalışarak 390.000 ton cevher öğütmüştür.

AĞIRLIK

Değirmen kauçuk astarlarının ağırlığı çelik astara nazaran yaklaşık %75 daha az olduğundan değirmen yatakları ve yağlama sistemi arızaları minimuma inmektedir.

SIZDIRMAZLIK

Çelik astar ve lifterbar civatalarının delikleri sık sık deforme olabilir. Buralardan meydana gelebilecek sızıntılar değirmenin yataklarına ulaşabilmekte ve yatağa zarar vermektedir. Kauçuk astarda sızdırmazlık sağlanmış durumdadır.

SES SÖNÜMLEMESİ

Kauçuğun sesi izole etme ve emme özelliğinden dolayı fabrika içinde gürültü minimuma inmekte,daha sağlıklı çalışma ortamı sağlanmaktadır.

EKONOMİKLİK

Kauçuk astar öğütülen cevher tonajı başına düşen birim maliyeti çelik astara nazaran her zaman daha düşük olmaktadır. Aşağıdaki liste, çeşitli değirmenlerde FKK'nın değişik astar imalatının çalışma saatlerini göstermektedir.

FKK değirmen astarları için karar verdiğinizde güvenilir servis organizasyonumuzdan yararlanabilirsiniz. Tecrübeli teknik elemanlarımızla her zaman müşterilerimizin çok yakınında ve emrinde olacağız.

Ürünlerimiz cevher hazırlama endüstrisi ile sıkı işbirliğimizin sonucunda geliştirilmiş ve imal edilmiştir. FKK değirmen astarlarının dizaynı ve üretimi problem çıkarması istenmeyen uygulamalar için geliştirilmiştir. Komple değirmen astarı programımızın bir parçası olarak öğütme işleminizi geliştirmek için teknolojimizden yararlanabilirsiniz.

Bilindiği gibi, mal veya hizmet üreten firmaların ana gayesi, gerek milli ve gerekse milletierarası pazarlarda kalite ve fiyat yönünden rekabet gücüne sahip olmaktır. Bu hususların gerçekleşmesinde laboratuvara çok önemli görevler düşmektedir.

Firmamız,modern cihazlarla teçhiz edilen laboratuvarı sayesinde mamul kalitesini talep edilen seviyede tam kontrol altında tutarak, yukarıda özetlenen amacı gerçekleştirmiştir.

Müşterilerimizin özel isteklerine göre üretim yapabiliriz.

• Aşınma ve darbeye dayanma.

• Yüksek eleme kapasitesi.

• Kolay montaj, kolay değişim.

• Daha iyi çalışma şartları, sessiz çalışabilme imkanı.

• Elenen malzeme zarar görmez.

• Düşük eleme maliyeti.

• Tel ve sac eleklere oranla çok daha uzun ömürlüdür.

• Poliüretan eleklerin esnek olması, diğer malzemeleri tutmama ve yapışmama özelliği, elek deliklerinin aşağıya doğru konik olması nedeniyle de elekte tıkanma olmamakta, elek kendini temizlemektedir.

• Elek yüzeyinin düzgünlüğü nedeniyle elenen malzeme yüzeye daha eşit yayılmaktadır.

• Cevher

• Kum ve çakıl

• Kırılmış taş

• Sinter

• Pelet

• Kok kömür

FKK GÜNEY OTO LASTİK TAKOZ SAN. TİC. A.Ş.

FKK GÜNEY OTO LASTİK TAKOZ SAN. TİC. A.Ş.

Bu sitede, hizmet sunmak, trafiği analiz etmek için Google'a ait çerezler kullanılır. Bu siteyi kullanımınız hakkındaki bilgiler Google ile paylaşılır. Bu siteyi kullanarak, sitede çerezlerin kullanılmasını kabul etmiş olursunuz.